application area

Aviation and aerospace

Aviation and aerospace

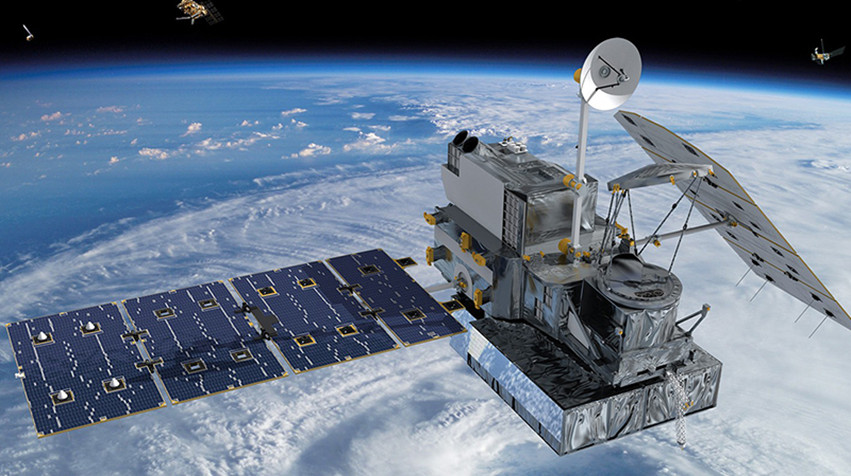

Space-grade chips, as a key component of space technology, play a crucial role. They are widely used in satellites, rockets, space stations, and other spacecraft to provide strong support for the normal operation of spacecraft. Electronic equipment systems are the important support for Starlink, Mars exploration probe, Yutu, Chang'e, etc. Space-grade chips are the heart of aviation and aerospace electronic equipment. Xilinx's space-grade FPGA chip is said to cost around 5 million yuan per unit, making it the most expensive chip ever. The price of the space CPU for the BeiDou satellite is 9 million yuan per board. According to Lin Baojun, the chief designer of the BeiDou-3 system, this price is several times cheaper than before. Generally speaking, chips can be divided into space-grade, military-grade, industrial-grade, and consumer-grade. The chips we were cut off from by the US in recent years are consumer-grade chips, while space-grade and military-grade have been blocked by the West for a long time. The working principle of space-grade chips is similar to that of ordinary chips, both of which realize the processing and transmission of information based on the characteristics of semiconductor materials. However, due to the extremely harsh operating environment, space-grade chips need to be specially optimized and improved in terms of design, manufacturing, and testing. Firstly, in terms of design, space-grade chips need to meet higher performance requirements. Due to the need for spacecraft to operate stably for a long time in space and without on-site repairs, space-grade chips must have high reliability, long lifespan, and low power consumption. Additionally, to adapt to the radiation environment in space, space-grade chips need to use special materials and structures to enhance their radiation resistance. In terms of manufacturing, space-grade chips require more refined manufacturing processes. Since spacecraft have strict weight requirements, space-grade chips need to ensure performance while minimizing size and weight. Furthermore, to ensure the quality and reliability of space-grade chips, strict quality control and environmental adaptation testing are required during manufacturing. Finally, in terms of testing, space-grade chips require more comprehensive testing and verification. Since the operating environment of spacecraft is extremely harsh and on-site repairs are not possible, space-grade chips need to be fully tested and validated before launch to ensure their stability and reliability in space. During testing, environmental factors such as radiation, temperature, and vacuum in space need to be simulated to comprehensively evaluate the chip's performance.

The main features of space-grade chips are as follows: High reliability: Due to the extremely harsh operating environment in space, where repairs cannot be performed on-site, space-grade chips need to have extremely high reliability. Strict quality control and environmental adaptation tests are required in design, manufacturing, and testing to ensure stability and reliability in space. Long lifespan: Spacecraft in space often operate for several years or even decades, so space-grade chips need to have a long lifespan. The design and material selection need to take into account the lifespan of the chip to ensure that it can maintain stable performance throughout the mission. Low power consumption: Due to the limited energy supply on spacecraft, space-grade chips need to have low power consumption. The design needs to use low-power circuit structures and algorithms to reduce energy consumption. Radiation resistance: Space-grade chips are exposed to a high-energy particle and cosmic ray environment in the space environment of the spacecraft. These particles and rays penetrate the shielding of the spacecraft and interact with the material of the components to produce radiation effects, causing the degradation of device performance or abnormal function, affecting the in-orbit safety of the spacecraft and having a serious impact on the performance and stability of the chip. Therefore, space-grade chips require special materials and structures to enhance their radiation resistance. For example, special doping techniques, shielding layers, and isolation structures can be used to improve the chip's radiation resistance. Miniaturization: Since the weight requirements for spacecraft are very strict, space-grade chips need to minimize volume and weight while ensuring performance. This requires the use of more advanced process technologies and optimized design to achieve. Security: The safety of spacecraft is of paramount importance. Therefore, space-grade chips need to have high security features, capable of withstanding various malicious attacks and interference. In design, encryption techniques, protection mechanisms, and security strategies can be used to ensure the chip's security.

The most important criterion for space-grade chips is not computing performance, but their ability to adapt to the space environment. In space, there are large amounts of high-energy particles and cosmic rays. These particles and rays produce radiation effects that seriously affect the operation of chips.According to statistics, during the 15 years from 1971 to 1986, the 39 synchronous satellites launched abroad experienced a total of 1,589 failures, of which 1,129 failures were related to space radiation. In addition, the extreme temperature differences in space will also affect the performance of chips. The research and development costs of overcoming these conditions are much higher than those of supporting application mobile chips. Why can we bear such high prices? Because space-grade chips do not have the demand for mass production, one for one hole, so they can research without considering the cost. China's current space-grade chips have achieved independence and self-reliance, unlike in the past when we could only rely entirely on imports. It is precisely because of the blockade imposed by Western countries that space-grade chips have had to take the difficult path of independent innovation. The main direction of this path is independent research and development, and the second is the use of open-source code redesign. The chip used by the Chang'e-4 probe during launch was still imported from the United States, the ATMEL AT697 chip, with prices ranging from 300,000 to over 1 million yuan. With the rise of domestic chips, China launched two domestic chips on the Beidou dual-star satellite in 2015, with a cost of only tens of thousands of yuan per chip. In 2017, China developed the Longchip 1E300, whose performance indicators have reached the level of US space-grade chips. With the government's attention and the emergence of talents, China is sure to make continuous progress in the research and manufacturing of space-grade chips, narrow the gap with developed countries, and ultimately achieve surpassing them.